How to Stop Porosity in Your Welds

Share

What is Porosity in Welding?

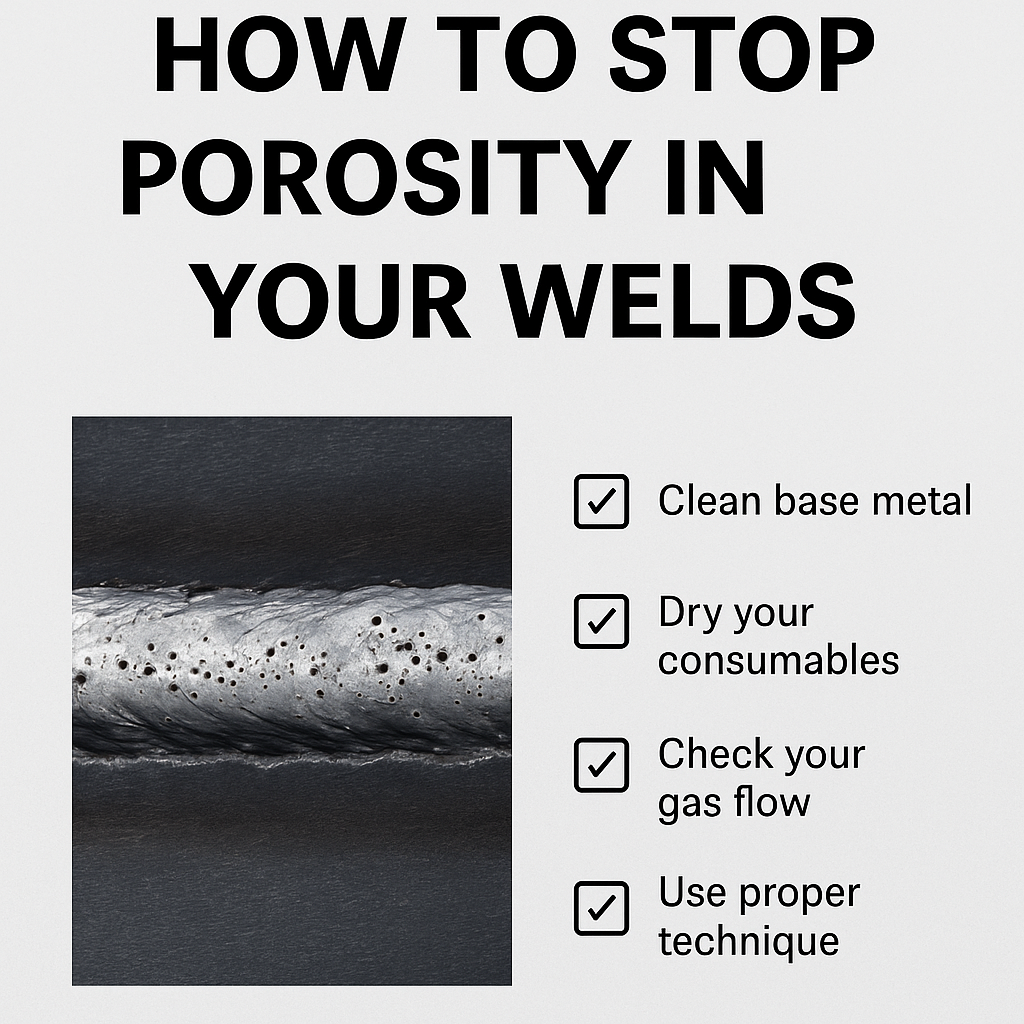

Porosity occurs when tiny cavities or bubbles form inside the weld metal. These voids are caused by gas being trapped as the molten weld pool solidifies. While porosity might look minor on the surface, it significantly reduces the strength of the weld and can cause premature failure.

There are different types of porosity:

-

Surface porosity – visible pinholes on top of the weld bead.

-

Distributed porosity – scattered pores throughout the weld.

-

Wormhole porosity – elongated pores often hidden inside the weld.

Each type weakens the weld and usually points to a problem in technique, materials, or gas coverage.

Why Porosity is a Serious Problem

-

Reduced strength – Pores act as stress points, making the weld more likely to crack.

-

Poor appearance – Visible pinholes make the weld look unprofessional.

-

Failed inspections – Porosity is a common reason for welds failing quality control checks.

-

Rework costs – Grinding out and re-welding takes time and increases consumable use.

Preventing porosity isn’t just about making a weld look clean — it’s about ensuring safety, reliability, and efficiency.

Common Causes of Weld Porosity

Porosity can result from several factors. Understanding these causes makes it easier to troubleshoot and correct them.

1. Contaminated Base Metal

Oil, grease, rust, paint, and moisture on the surface release gas when heated, which gets trapped in the weld.

Solution: Always grind, wire-brush, or chemically clean the joint area before welding. For aluminium, use a stainless steel brush dedicated to aluminium only.

2. Moisture in Consumables

Electrodes and filler rods can absorb moisture from the air, which releases hydrogen gas during welding.

Solution: Store electrodes in sealed containers or rod ovens. Keep MIG/TIG wire spools dry and covered.

3. Poor Shielding Gas Coverage

If your shielding gas flow is too low, too high, or disrupted by drafts, oxygen and nitrogen can contaminate the weld pool.

Solution:

-

Set your gas flow correctly (10–15 L/min indoors, 15–20 L/min outdoors).

-

Check for leaks in hoses, regulators, and fittings.

-

Avoid welding in draughty conditions or use screens to block airflow.

4. Incorrect Technique

Holding the torch too far away, using the wrong angle, or moving too fast can cause poor gas shielding and turbulence in the weld pool.

Solution:

-

Maintain the correct stick-out (typically 10–15mm for MIG).

-

Keep a steady travel speed.

-

Use the correct torch angle (10–15° push or drag depending on the process).

5. Defective or Dirty Equipment

Clogged nozzles, worn liners, or incorrect consumables can disturb gas flow and trap contaminants.

Solution: Regularly inspect your torch, replace consumables, and keep your nozzle and contact tip clean.

How to Prevent Porosity Step-by-Step

-

Prepare your material properly

-

Grind off rust, paint, and mill scale.

-

Degrease oily or dirty surfaces with acetone or appropriate cleaner.

-

-

Check your consumables

-

Store rods and wires properly.

-

Replace damaged or rusty spools.

-

-

Set up your gas correctly

-

Use the right gas for the process (e.g., Argon/CO₂ mix for MIG mild steel, pure Argon for TIG).

-

Adjust flow rate according to environment.

-

Check for leaks with soapy water.

-

-

Maintain your equipment

-

Clean nozzles regularly.

-

Replace worn contact tips and liners.

-

Ensure regulators and flowmeters are accurate.

-

-

Improve your technique

-

Maintain consistent torch angle and travel speed.

-

Avoid excessive stick-out.

-

Practice steady hand movements to reduce turbulence.

-

Advanced Tips for Professionals

-

Use dual-stage regulators – They provide steady gas flow even as cylinder pressure drops, reducing fluctuations that can cause porosity.

-

Preheat in cold conditions – Helps remove moisture and reduces hydrogen cracking.

-

Back purging (TIG welding stainless) – Prevents oxidation and porosity on the root side of the weld.

-

Shielding gas quality – Cheap or contaminated gas can introduce impurities. Stick with reputable suppliers.

Troubleshooting Checklist

If you’re still seeing porosity, run through this quick checklist:

-

Is the material clean and dry?

-

Is your shielding gas flowing at the correct rate?

-

Are there leaks in your hoses or connections?

-

Are your consumables in good condition?

-

Is your torch angle and stick-out correct?

Final Thoughts

Porosity might be one of the most common welding problems, but it’s also one of the easiest to prevent with the right preparation and setup. Clean materials, good gas coverage, and proper technique are the key.

If you’re constantly fighting porosity, it might be time to upgrade your gas setup or replace worn equipment. Check out our Gas Equipment Collection for regulators, flowmeters, and accessories designed to keep your welds clean and consistent.