Dynaweld

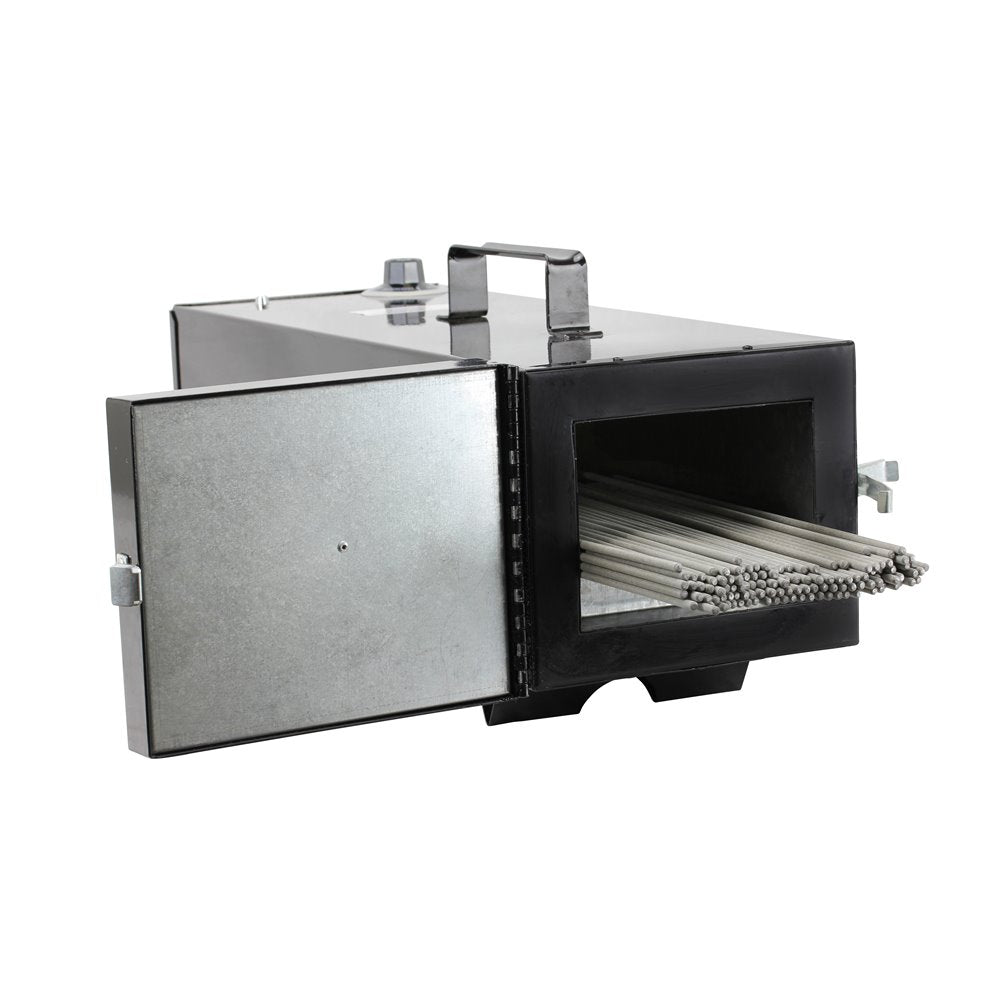

BOSSWELD Phoenix Drying Ovens

BOSSWELD Phoenix Drying Ovens

SKU:500112

Low stock: 1 left

Couldn't load pickup availability

BOSSWELD Phoenix Electrode drying ovens

• The Phoenix drying ovens have been designed to maintain your Low Hydrogen electrodes at the best possible temperature during use, as it has excellent insulation properties which result in lower heat loss during heating and has an adjustable temperature control which you can adjust to maintain optimum electrode conditioning.

• The construction and design of the Pheonix range of electrode ovens, has taken into consideration the harsh environment which they are used, which will give the operators reliability when it counts.

• The power leads are removable from the boxes and are interchangeable between models, which make it safer when transporting to the job.

• In the range of Pheonix electrode drying ovens, there are four models to choose from, one will have an application which will suit your needs. Why use an electrode Drying oven?

• Excessive levels of moisture in an electrode will be transferred to a weld metal and will cause weld defects such as Hydrogen induced cracking, which is not directly visible and can take some time to be revealed in the welded structure.

• Low Hydrogen Electrodes are designed to have lower moisture levels than General Purpose electrodes and when using these electrodes, to obtain the maximum benefit when using Low Hydrogen electrodes, it is important to have these electrodes conditioned during use. This conditioning will ensure that the moisture content is kept at a critical low level and the electrodes are used in their intended form.

• Once the electrode packet has been opened, the electrode flux is exposed to the environment and will increase the moisture content of the electrode flux. If it has been exposed for a prolonged period, they must be re baked in accordance to the manufacturer’s specification.

• To make sure this doesn’t happen to you, make sure you store your Low Hydrogen electrodes in a BOSSWELD Pheonix electrode drying oven.

• The Pheonix Electrode Drying ovens are designed to maintain electrode condition once the electrodes have been removed from the original packaging

Features

• Strong robust design

• Excellent insulation properties, reducing heat loss

• Adjustable temperature control

• Thermostat knob protection

• 240v 10 Amps supply

• Removable primary lead

• Interchangeable primary lead between models

• 1 year warranty

- Customer Promise

- Price Match

- 30-Day Returns

Product Information & Advice

Product Information & Advice

Need More Information?

Need more details? If you have questions about usage, availability, or specs, our team is here to help. Reach us via 24/7 live chat, our contact page, or call (02) 9729 1127 during business hours.

Shipping & Delivery

Shipping & Delivery

We deliver Australia-wide and internationally.

- Australia Post (Parcel & Express)

- Courier Network: TNT, Toll, Northline, Allied, Hunter, Aramex, Go Logistics, UBER (2hr Sydney Metro), and more

With our wide delivery network, you’ll get your order quickly and cost-effectively.

Same-Day Click & Collect

Same-Day Click & Collect

Order before 2:00 PM, and if in stock, collect the same business day. We’ll notify you as soon as your order is ready.

Warranties and Returns

Warranties and Returns

- Manufacturer Warranties + full coverage under Australian Consumer Law

- 30-Day Returns on unopened/unused products (customer pays return shipping)

- Defective Products: free return and replacement, handled with priority

Shop with confidence — we’ve got you covered.

Share

-

Customer Promise

Provide FeedbackAt our core, we provide personalised, honest service to every customer, regardless of their size, budget, or expertise.

-

Expert Advice

Contact usWhy settle for generalists when you can benefit from specialists? With over two decades of experience in the welding and electrical supply industry, we offer tailored advice to meet your specific needs.

-

See it in-person?

Visit usEnjoy a hands-on shopping experience at our Smithfield storefront, where a personalised journey awaits you. Our doors are open, and we can’t wait to welcome you!

Welding Guides

View all-

Choosing the Best Welding Helmet: A Complete Guide

Discover how to choose the best welding helmet for your needs. Learn about auto-darkening lenses, shade levels, viewing size, comfort, and safety features.

Choosing the Best Welding Helmet: A Complete Guide

Discover how to choose the best welding helmet for your needs. Learn about auto-darkening lenses, shade levels, viewing size, comfort, and safety features.

-

How to Stop Porosity in Your Welds

Porosity in welds creates weak spots and poor finishes. Learn the causes of weld porosity and how to prevent it with proper technique, preparation, and equipment.

How to Stop Porosity in Your Welds

Porosity in welds creates weak spots and poor finishes. Learn the causes of weld porosity and how to prevent it with proper technique, preparation, and equipment.

-

What is TIG Welding?

Tungsten Inert Gas (TIG) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. A filler rod is...

What is TIG Welding?

Tungsten Inert Gas (TIG) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. A filler rod is...