Klingspor

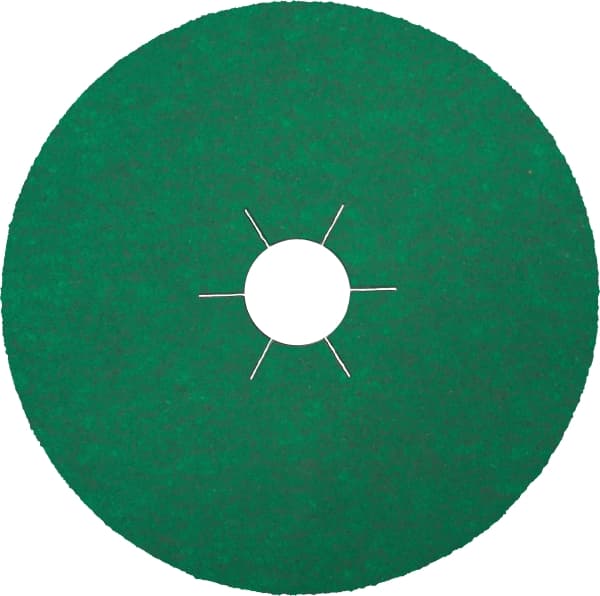

KLINGSPOR CS 570 Fibre discs for Stainless steel, Aluminium

KLINGSPOR CS 570 Fibre discs for Stainless steel, Aluminium

SKU:204823

In stock

Couldn't load pickup availability

Fibre discs CS 570 – fibre discs that deliver a high removal rate on stainless steel, steel, NF metal and aluminium

Grinding work on metal presents a particularly daunting challenge to any abrasive. Metals prove to be difficult materials as they are tough, yet exceptionally hard at the same time. The most formidable of these metals are stainless steel and high-alloy steels, so-called super alloys. The fibre discs CS 570 tackle these challenges with an extra hard and ultra tough abrasive grain made of zirconia alumina that is bonded to a vulcanised fibre backing plate with a strong synthetic resin. The fibre disc CS 570 possesses characteristics that make it a particularly good choice for processing stainless steel and aluminium:

- Cool grinding thanks to multibond

- Close coating

- Grain made of zirconia alumina

The self-sharpening effect provided by the zirconia alumina grain

The zirconia alumina used for the fibre discs CS 570 by Klingspor is a synthetically made grain with a crystalline structure that is exceptionally hard and tough. The sharp edges of natural abrasives made of quartz, emery or garnet wear out over time, resulting in reduced abrasive performance. Synthetically made zirconia alumina acts differently. Wear causes individual portions to break out of the crystalline structure, leaving behind new, sharp edges. This will result in a uniform scratch pattern at a continuous removal rate and a long service life.

Prevention of overheating

Fibre discs are perfect for use in high temperatures. The cool grinding ensured by the green multibond prevents premature overheating and discolouration of the metal on the workpiece, allowing for smooth operation even at a high contact pressure and high speeds. For safety reasons, the maximum operating speed of a fibre disc when fitted to a backing pad must not exceed 80 metres per second. The following permissible values are designed to keep the speed within this limit:

- For discs with a diameter of 115 mm: 13,300 revolutions per minute

- For discs with a diameter of 125 mm: 12,200 revolutions per minute

- For discs with a diameter of 180 mm: 8,500 revolutions per minute

For use with the fibre discs CS 570

Available for the fibre discs CS 570 are matching backing pads, ST 358 A ribbed hard and ST 358 smooth medium. The backing pad must be selected according to the intended application. The medium backing pad is suited for applications requiring a uniform finish as it conforms perfectly to the contours of the workpiece. Its properties make this backing pad ideal for finer grinding work, surface grinding or grinding contours. The hard backing pad is used for rough grinding at high removal rates. It performs especially well when used for deburring and aggressive grinding.

- Customer Promise

- Price Match

- 30-Day Returns

Product Information & Advice

Product Information & Advice

Need More Information?

Need more details? If you have questions about usage, availability, or specs, our team is here to help. Reach us via 24/7 live chat, our contact page, or call (02) 9729 1127 during business hours.

Shipping & Delivery

Shipping & Delivery

We deliver Australia-wide and internationally.

- Australia Post (Parcel & Express)

- Courier Network: TNT, Toll, Northline, Allied, Hunter, Aramex, Go Logistics, UBER (2hr Sydney Metro), and more

With our wide delivery network, you’ll get your order quickly and cost-effectively.

Same-Day Click & Collect

Same-Day Click & Collect

Order before 2:00 PM, and if in stock, collect the same business day. We’ll notify you as soon as your order is ready.

Warranties and Returns

Warranties and Returns

- Manufacturer Warranties + full coverage under Australian Consumer Law

- 30-Day Returns on unopened/unused products (customer pays return shipping)

- Defective Products: free return and replacement, handled with priority

Shop with confidence — we’ve got you covered.

Share

-

Customer Promise

Provide FeedbackAt our core, we provide personalised, honest service to every customer, regardless of their size, budget, or expertise.

-

Expert Advice

Contact usWhy settle for generalists when you can benefit from specialists? With over two decades of experience in the welding and electrical supply industry, we offer tailored advice to meet your specific needs.

-

See it in-person?

Visit usEnjoy a hands-on shopping experience at our Smithfield storefront, where a personalised journey awaits you. Our doors are open, and we can’t wait to welcome you!

Welding Guides

View all-

Choosing the Best Welding Helmet: A Complete Guide

Discover how to choose the best welding helmet for your needs. Learn about auto-darkening lenses, shade levels, viewing size, comfort, and safety features.

Choosing the Best Welding Helmet: A Complete Guide

Discover how to choose the best welding helmet for your needs. Learn about auto-darkening lenses, shade levels, viewing size, comfort, and safety features.

-

How to Stop Porosity in Your Welds

Porosity in welds creates weak spots and poor finishes. Learn the causes of weld porosity and how to prevent it with proper technique, preparation, and equipment.

How to Stop Porosity in Your Welds

Porosity in welds creates weak spots and poor finishes. Learn the causes of weld porosity and how to prevent it with proper technique, preparation, and equipment.

-

What is TIG Welding?

Tungsten Inert Gas (TIG) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. A filler rod is...

What is TIG Welding?

Tungsten Inert Gas (TIG) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. A filler rod is...