Klingspor

KLINGSPOR NPA500 - Strips/Sheets for Paint, Varnish, Plastic, Stainless steel

KLINGSPOR NPA500 - Strips/Sheets for Paint, Varnish, Plastic, Stainless steel

SKU:342857

In stock

Couldn't load pickup availability

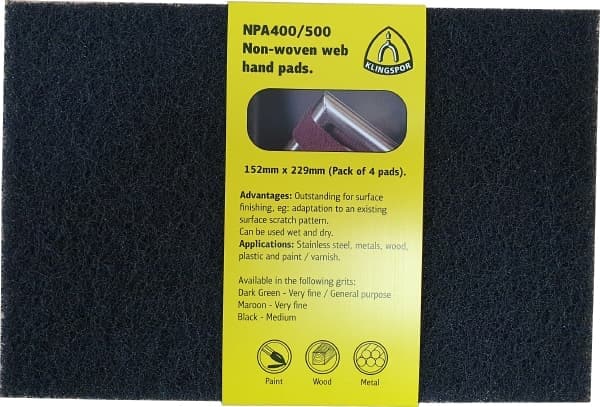

Klingspor non-woven web hand pads NPA 500 – non-woven web hand pads for both wet and dry sanding

Designed for a wide range of different materials, the non-woven web hand pads NPA 500 produce a perfect hand sanding finish every time. The silicon carbide material provides for a smooth scratch pattern without any swirl marks. The NPA 500 abrasive is available in 3 grades, which are colour-coded for easy identification:

- “Medium” – medium: Colour black,

- “Ultra fine” – ultra fine: Colour grey,

- “non-abrasive” – with no grit: Colour white.

Hand sanding with the non-woven web hand pads NPA 500 by Klingspor

The application options of the NPA 500 are legion: whether used on stainless steel, paints, varnish, filler plastic – the NPA 500always produces impeccable results during hand sanding.

NPA 500 is a non-woven web you need to achieve the perfect finish

The non-woven web creates a finish on the surface. The non-woven has an open meshes structure that allow for the collection and subsequent removal of dust and debris. The structure, thereby, effectively prevents clogging, giving the non-woven web hand pads an exceptionally long service life.

Intended purpose of the Klingspor NPA 500

The Klingspor non-woven web hand pads NPA 500 are particularly well suited for blending surfaces. They are the perfect hand sanding for graining intricate contours. When used for this type of material processing, the non-woven web hand pads NPA 500perform especially well on flat surfaces. Its resistance to water makes these non-woven web hand pads suitable for both dry and wet sanding. The standard size of the non-woven web hand pads NPA 500 is 152 x 229 mm (width x length) – one packing unit holds 20 sheets. Additional sizes and dimensions and orders for larger quantities are available at any time upon request.

- Customer Promise

- Price Match

- 30-Day Returns

Product Information & Advice

Product Information & Advice

Need More Information?

Need more details? If you have questions about usage, availability, or specs, our team is here to help. Reach us via 24/7 live chat, our contact page, or call (02) 9729 1127 during business hours.

Shipping & Delivery

Shipping & Delivery

We deliver Australia-wide and internationally.

- Australia Post (Parcel & Express)

- Courier Network: TNT, Toll, Northline, Allied, Hunter, Aramex, Go Logistics, UBER (2hr Sydney Metro), and more

With our wide delivery network, you’ll get your order quickly and cost-effectively.

Same-Day Click & Collect

Same-Day Click & Collect

Order before 2:00 PM, and if in stock, collect the same business day. We’ll notify you as soon as your order is ready.

Warranties and Returns

Warranties and Returns

- Manufacturer Warranties + full coverage under Australian Consumer Law

- 30-Day Returns on unopened/unused products (customer pays return shipping)

- Defective Products: free return and replacement, handled with priority

Shop with confidence — we’ve got you covered.

Share

-

Customer Promise

Provide FeedbackAt our core, we provide personalised, honest service to every customer, regardless of their size, budget, or expertise.

-

Expert Advice

Contact usWhy settle for generalists when you can benefit from specialists? With over two decades of experience in the welding and electrical supply industry, we offer tailored advice to meet your specific needs.

-

See it in-person?

Visit usEnjoy a hands-on shopping experience at our Smithfield storefront, where a personalised journey awaits you. Our doors are open, and we can’t wait to welcome you!

Welding Guides

View all-

Choosing the Best Welding Helmet: A Complete Guide

Discover how to choose the best welding helmet for your needs. Learn about auto-darkening lenses, shade levels, viewing size, comfort, and safety features.

Choosing the Best Welding Helmet: A Complete Guide

Discover how to choose the best welding helmet for your needs. Learn about auto-darkening lenses, shade levels, viewing size, comfort, and safety features.

-

How to Stop Porosity in Your Welds

Porosity in welds creates weak spots and poor finishes. Learn the causes of weld porosity and how to prevent it with proper technique, preparation, and equipment.

How to Stop Porosity in Your Welds

Porosity in welds creates weak spots and poor finishes. Learn the causes of weld porosity and how to prevent it with proper technique, preparation, and equipment.

-

What is TIG Welding?

Tungsten Inert Gas (TIG) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. A filler rod is...

What is TIG Welding?

Tungsten Inert Gas (TIG) welding is the process in which an arc is formed between a tungsten electrode and the workpiece to join the metals together. A filler rod is...